Approaching Life Cycle Thinking from a design mindset

The harsh reality is, most of what we (the world) create and consume ends up in the landfill. As designers, we need to step up and own our responsibility. We need to proactively change our approach if we are to make any dent in the world’s environmental footprint.

Here at Locus, we have championed sustainability through design since the day we opened our doors in 2002. In the past, this passion has often fallen on deaf ears, but we are now seeing increasing interest in this space from consumers, business and governments alike. The landscape is changing – and boy, are we pleased.

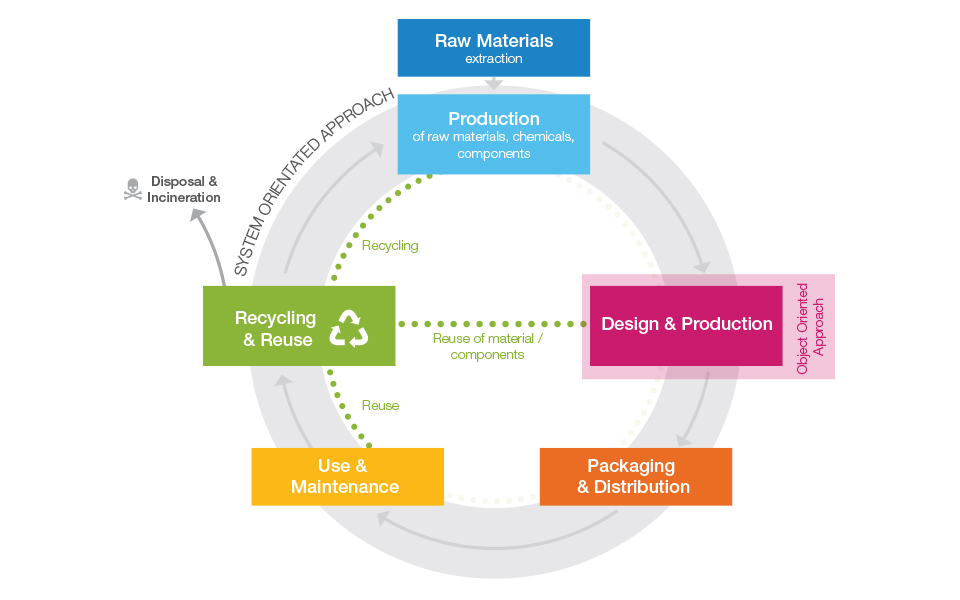

One concept we have long been a fan of is the concept of Life Cycle Thinking (LCT). Life Cycle Thinking is about going beyond the traditional focus on manufacturing processes to include environmental, social and economic impacts of a product over its entire life cycle. It means thinking about a product through its entire value chain – from the raw materials and the energy used to create the product, through to the packaging, distribution, use, maintenance, and eventually recycling, reuse, recovery or final disposal.

In each life cycle stage, there is the potential to reduce the environmental impact and improve the performance of products. And that’s a great business proposition.

The product system

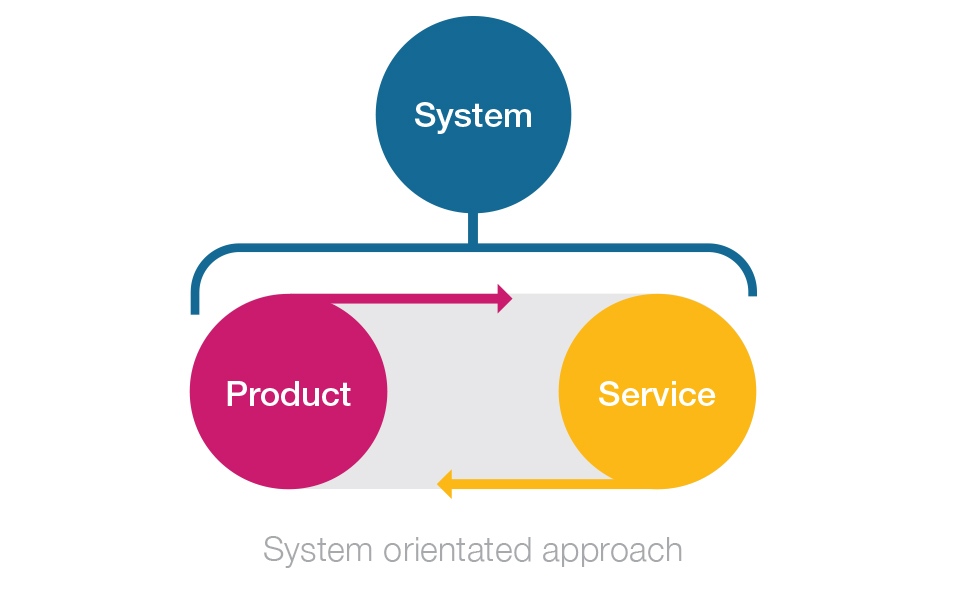

Traditionally, designers are taught to design objects, design tools are created to design objects, but LCT is a system concept. It involves thinking about a product as a system which also includes the service associated with it.

A product is a tangible commodity manufactured to be sold. It is capable of falling onto your toes and of fulfilling a user’s need. A service is an activity done for others (people or automation) with an economic value. A system encompasses the product and all associated services.

Think of UBER. The service includes the drivers and your whole booking/ride experience. The product is the app and the bank of servers somewhere in the world. Think of Patagonia (and sustainability leader in outdoor clothing and gear). The product is a piece of clothing that you buy, the service is the buying experience, including how they repair, reuse, and recycle the clothes through their programs.

In order to design the ‘system’, which incorporates the product and the service, it is helpful to understand and articulate both the functional unit and the core function of the system.

The Functional Unit

The ‘functional unit’ is a concept that originates within Life Cycle Assessment (LCA). It enables you to frame a product’s inputs and outputs and steps back from the product itself to describe the service provided. The primary purpose is to allow equitable comparison of very different methods of supplying the same service.

For example, if you’re comparing a glass bottle with a plastic bottle of milk, it is useful to define the functional unit as ‘The delivery of 1000 litres of Milk.’ With this functional unit, you can then compare the two solutions (glass bottle or plastic bottle in different capacities) through the product lifecycle in a way that allows direct comparison. For example, which takes more energy during the manufacturing process to deliver 1000 litres of milk? Do glass bottles use more or less raw material than plastic over 1000 litres of milk?

But the functional unit is an analytical description. We also need a design description to serve as a guide for the development of new ideas. This is what we refer to as the core function.

The Core Function

The ‘Core Function’ describes the key attributes of the product in simple, even poetic terms. It defines the core objective of your system and is a much-needed guide for designers and engineers.

For example, the bottle of milk. The customer is not specifically buying a bottle (either glass or plastic). They simply want fresh, delicious milk when and where they need it. So the core function is ‘Convenient fresh milk’.

Functional Unit – The Delivery of 1000 litres of milk

Core Function – Convenient Fresh Milk

Lifecycle Thinking

Lifecycle Thinking, or the Circular Economy, requires thinking about the system through the entire lifecycle and value chain.

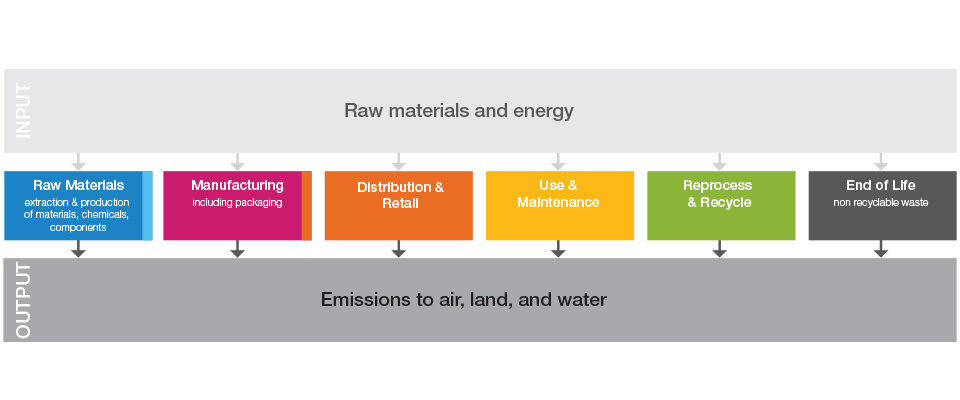

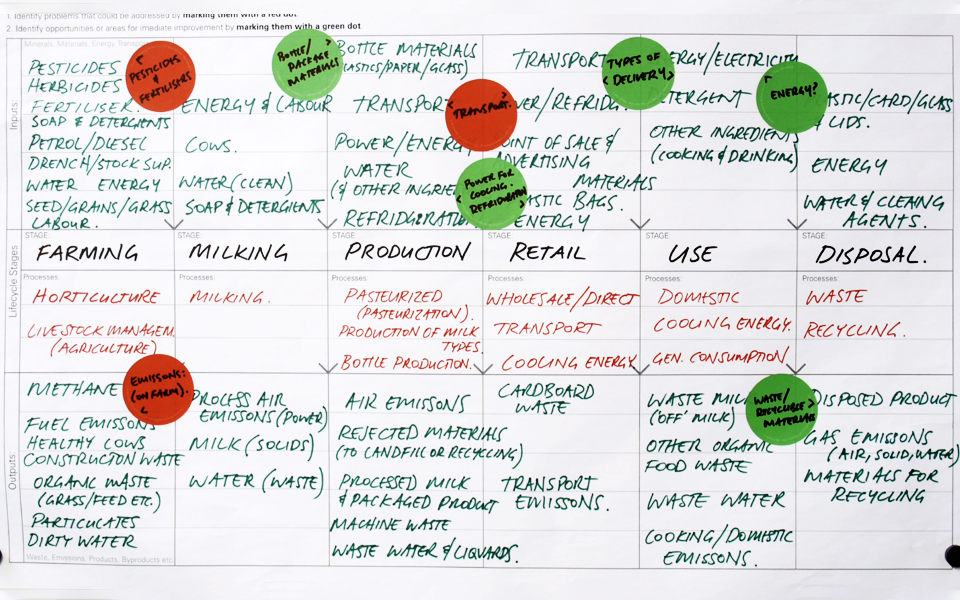

A helpful method we use is to take a simplified view of the lifecycle and examine the inputs and outputs at each stage. So starting with the core function (in our example ‘convenient fresh milk’) we list out the inputs and outputs at each step of the lifecycle – from farming through to disposal.

At first pass, it doesn’t need to be too technical and can be done in a workshop involving key team members. In the example worksheet below, the team identified pesticides and fertiliser inputs along with methane emission outputs during the farming phase as ‘trouble spots’. At the same time, they also identified several opportunities, such as exploring types of delivery or recyclability of materials.

So you can see a simple exercise like this can identify hotspots during the lifecycle with the most significant environmental impacts. You can also compare two or more systems to compare their relative environmental impacts. And the beauty is, the exercise may bring up problems and opportunities that can be addressed by your business, if not right now, then at some point soon. It can provide a real focus for where to apply resource and ways to reduce the environmental footprint for your’ product system’. In some cases, it can even be a much-needed wakeup call!

Want to get started with Life Cycle Thinking but don’t know how? Get in touch to find out how we can help you and your company make inroads towards improved sustainability (and business outcomes).

Want to read more on creativity, design, product development and innovation? Go to our Six Lenses Blog.

Comments